porducts

您当前的位置:首页 > News > Company Information > Introduce the electrophoresis process equipment

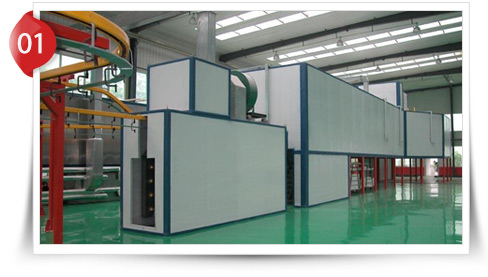

Equipment, electrophoresis equipment are the most important: the electrophoresis tank, electrophoresis power, ultrafiltration machine, pure water machine, water washing tank, oven. Electrophoresis equipment in general is to put these are installed, if the customer requirements is not high, the use of pure water is not, can buy barreled pure water instead of. So the entire line of investment will be reduced a lot, tens of thousands of pieces of money can get. The high cost of pure water machine. Electrophoresis of the complete sets of equipment is also called line electrophoresis, electrophoresis line is divided into manual, semi-automatic and automatic and some other types.

电泳设备工艺介绍

Introduce the electrophoresis process equipment

1、工件上挂需注意:

1, the workpiece hanging should pay attention to:

(1)工件与挂具的接触点是否导电良好;

(1) the point of contact with the workpiece rack whether good conductivity;

(2)带锈的工件要返回除锈;

(2) the workpiece with rust rust to return;

(3)油污过重的工件要先进行一遍线外脱脂;

(3) the workpiece oil heavy to again line degreasing;

备注:针对油脂较多或锈蚀严重工件需进行线外处理,工序如下:

Note: for more serious or rust oil workpiece need line processing, procedure is as follows:

脱脂 + 2次水洗+酸洗+2次水洗+中和

Debinding + washing 2 times + + 2 times washing + neutralizes acid pickling

2、热水洗:

2, hot water washing:

对于浸渍式,一般省去该道工序。对于连续式,一般采用50-70℃的热水喷淋,其主要目的是降低油脂的粘度、活化油脂。

For immersion, generally omit the procedure. For continuous, generally use the hot water spraying 50-70 degrees, its main purpose is to reduce the viscosity of oil, the activation of grease.

3、脱脂:

3, skim:

工件上的油脂必须除去,否则会影响磷化、涂装品质。对于钢铁件,一般采用带表面活性剂的碱性脱脂剂进行脱脂,其特点是脱脂效果好,效率高,且价格便宜。

The workpiece grease must be removed, otherwise it will affect the quality of the phosphating, coating. For the steel parts, the general use of alkaline degreasing agent with surface active agent is characterized by degreasing, degreasing effect is good, the efficiency is high, and the price is cheap.

在连续式涂装生产中,脱脂一般设为预脱与主脱两道工序,其作用是更有效地除去工件上的油脂。

In the continuous coating production, skim the general set as pre removal and the main removal of two processes, its role is more effective to remove the grease on the workpiece.

4、水洗:

4, washing:

用自来水进行喷淋或浸渍水洗,一般设二至三道工序,其作用亦是为了加强水洗效果。脱脂之后的水洗虽为辅助工序,但同样要引起足够的重视,因残脱脂剂对磷化、涂装均会造成有害的影响。

Spray or immersion washing with tap water, usually set two or three steps, and its role is to enhance the washing effect. Degrease after washing although the auxiliary process, but also to cause enough attention, because of the residual degreasing agent on the phosphating, coating will cause harmful effects.

5、表调:

5, watch:

采用锌系磷化工艺均需设有表调工序,其作用为:改变金属表面的微观结构,促使磷化过程中生成结晶细小、均匀、致密的磷化膜。表调的方式有多种,一般采用胶体钛盐物理化学吸附法

With zinc series phosphating process are required to a surface conditioning process, its function is: change the microstructure of the metal surface, phosphating film prompted phosphating is produced in the process of fine crystallization, uniform, dense. Clocks in different ways, generally using adsorbing colloid titanium salt physical chemistry method

6、磷化:

6, phosphating:

磷化大体上可分为铁系磷化与锌系磷化两类。铁系磷化不需设表调工序,铁系磷化膜呈彩虹色,膜较薄,其缺点是涂膜的耐蚀性较锌系磷化差。良好的锌系磷化膜外观呈灰白色,均匀、致密、无金属亮点。磷化的目的主要是为了提高涂膜的耐蚀性。

Phosphating generally can be divided into iron phosphating and zinc phosphating two class. Iron phosphating without a surface conditioning process, iron phosphating film is a rainbow, with a thin membrane, the disadvantage is the corrosion resistance of the coating is zinc phosphating difference. Zinc phosphating film, good appearance of a white, uniform, compact, bright metal free. Phosphating is for the purpose to improve the corrosion resistance of coating.

7、水洗:

7, washing:

磷化后的水洗一般为喷淋或浸渍或二者相结合的方式进行,设二至三道水洗工序,其目的亦是为了有效地洗去工件上的磷化浮渣及磷化液,磷化液磷化后水洗的效果如何,亦将直接影响到电泳涂装品质。

Phosphating after washing for the general spraying or dipping or the combination of both two, set two to three water washing process, the purpose is to effectively wash away the workpiece phosphating scum and phosphating solution, how to wash effect of phosphating, will directly affect the electrophoretic coating quality.

水洗用水一般为工业用水。

Washing water for general industrial water.

8、纯水洗:

8, pure water wash:

洗去工件上所附带的大多数杂质离子。工件若带大量的各种杂质离子进电泳槽,对涂装品质、槽液的稳定性均会带来直接的负面影响。

Most of the impurity ion attached to wash away the workpiece. If the workpiece with a variety of impurity ions into the electrophoresis tank, stability of the coating quality, the bath will bring direct negative impact.

纯水洗结束至电泳槽之间设有一滴水,其主要目的是:

Water wash to the electrophoresis groove is arranged between the end of a drop of water, its main purpose is to:

(1)通过对滴水取样检测电导度,以检查纯水洗的质量,滴水的电导 率要求不超过50µS/cm,否则则需加大纯水之供水量;

(1) based on the drop of water sampling and testing of electrical conductance, quality to check the water washing, dripping water conductivity requirements of not more than 50 S/cm, otherwise, the need to increase the supply quantity of pure water;

(2)减少带入ED槽杂质离子的量;

(2) reduce the amount of impurity ions into the ED slot;

(3)对于一些错位的工件进行纠正,以确保良好之导电。

(3) to correct for the workpiece to some dislocation, to ensure good conductivity.

9、电泳:

9, electrophoresis:

工件进入电泳槽,于一定的条件下使涂料电沉积到工件上。

The workpiece into the electrophoresis tank, in certain conditions so that the coating electrodeposited onto the workpiece.

10、回收水洗:

10, recycling water washing:

电泳涂装不同于传统涂装,工件电泳获得一层水不溶性涂膜,电泳完毕出槽后,会在其表面附带出漆液,这些漆液需洗去,以避免不良现象的产生。同时,为提高涂料的利用率,又需对这些洗下来的漆液进行回收,故电泳之后 一般均采用3至4级回收水洗,以加强水洗质量与回收效果,实现回收水洗 的首要功能设备是UF,UF将电泳槽中的水“提取”出来,供回收水洗用,这样,方实现一个连续、平衡的水洗回收。

Electrophoretic coating is different from the traditional painting, workpiece electrophoresis obtain a layer of water insoluble coating, electrophoresis finished out of the slot, will be attached on the surface of the liquid paint, paint liquid to wash, to avoid undesirable phenomenon. At the same time, in order to improve the utilization of the coating, and the need to recover these wash down the paint liquid, so the electrophoresis after generally uses the 3 to 4 level to enhance the recovery of washing, washing quality and recovery effect, the primary function of the realization of recycling water washing equipment is UF, UF will be in the Electrocoat tank water "extraction", for the recovery of washing, thus, party to implement a continuous, balanced washing recovery.

11、后纯水洗:

After 11, the pure water washing:

工件经回收水洗后,其表面仍会残留少许的漆液、溶剂与各种杂质离子,需经一至二道纯水洗其洗去,以确保涂膜质量。

The workpiece by recovery after washing liquid, solvent, paint the surface will still be residual a little and various kinds of impurity ions, through one to two water wash wash, to ensure the quality of coating.

后纯水洗结束到烤炉之间需设一段滴水,其作用:

After the end of pure water washing to the oven between the need to set a drop of water, its role:

(1)、将工件上所附带的水吹掉、晾干,以避免带水入炉烘烤产生异常及能源浪费;

(1), will be attached on the workpiece, resulting in abnormal water blown dry, and waste of energy to avoid water into the furnace baking;

(2)、将导电不良未电泳上涂膜的工件取出重新处理。

(2), the workpiece is poor conductivity of electrophoresis coating removed without re treatment.

12、烘烤 :

12, baking:

电泳涂膜非自干型,需要较高的温度烘烤一定的时间方可使涂膜固化。烘烤条件视涂料的品种不同而有异,宇鹰公司ML-系列产品烘烤条件一般为:170℃-200℃ × 25min-15min

Electrophoretic coating non self drying type, the need of high temperature baking some time can make the curing of coating. As the varieties of paint baking conditions vary, Yu Ying company ML series products of baking conditions generally: 170 DEG C to 200 DEG C * 25min - 15min

涂膜是否已完全固化,业者可凭一定的经验进行直观判断,若较标准亮,则未烤干;则较标准哑,则为过烘烤。

The film is completely cured, the industry with some experience of intuitive judgment, if compared with standard bright, is not dry; it is standard dumb, for baking

专注电泳设备研发10年。全国十佳优秀电泳涂装设备企业之一,国际质量体系IOS9001认证。 已为富士康/比亚迪/吉利汽车/中国一汽等众多企业提供电泳设备产品和服务;在电动三轮车,汽配,轮毂、锯片、灯饰、五金等行业有着丰富的经验。

我司拥有电泳涂装线专业技术人员达70多人,产品远销韩、印尼、中东、越南、缅甸、俄罗斯等十多个国家和地区。且所有产品均自主生产,电泳涂装线配件都采用进口品牌或国产优质品牌以保障品质。

您只需要说明工件的材质,尺寸、产量、和所电泳的颜色,我司即可免费制作出一套量身定制的电泳生产线方案,让您一目了然。 同时可以短期内免费为您培训一批电泳现场操作人员以保证电泳生产车间的正常生产运行,并根据您的需要推荐经验丰富的电泳老师供您聘用。

我们不仅提供上门指导,上门安装电泳设备以及员工操作培训; 同时提供12个月的质量保证.为提高服务效率我司开通24小时直线售后服务,且在广东、浙江、江苏、河南、河北、陕西、北京、南京、辽宁等均设有经销商和办事处为您提供快捷的售后服务。

Projects Video

2023-02-10

2022-11-30

2022-11-30

2022-11-16

2022-10-25

2022-10-06

2022-09-29

2022-09-13

2022-09-06

2022-04-18

2022-03-22

2022-03-22

2022-03-10

2021-12-30

2021-12-29

2021-11-18