porducts

您当前的位置:首页 > News > Industry Information > How to choose the electrophoretic coating equipment

Electrophoretic coating is the workpiece and the corresponding electrode into the water soluble paint, after the power is switched on, rely on the physical and chemical effects of electric field produced by the resin, paint, pigment and filleron the object to be coated as a method of coating on the surface of the electrode uniform deposition forming water-insoluble film. Electrophoretic coating is an extremely complex process of electrochemical reaction, whichincludes at least the electrophoresis, electroosmosis, electrolysis,electrodeposition of four processes. Electrophoretic coating by deposition performance can be divided into the anode electrophoresis (workpiece isanode, coating is anionic) and cathode electrophoresis (workpiece cathode,paint is a cationic); press the power can be divided into DC and ACelectrophoresis electrophoresis; according to the process of method andconstant voltage and constant current method. At present widely in industry is used in anodic electrophoretic DC power supply constant voltage method.

1- after the workpiece surface processing; 2- power; 3- workpiece; 4- water for washing bath; 5- filter; 6- sedimentation tank; 7- circulation pump

Comparison of electrophoretic coating and other coating method, with the following characteristics:

(1) the water soluble paint, with water as the dissolution medium, saves a large amount of organic solvent, greatly reducing air pollution and harmful to environment, health and safety, and avoids the hidden trouble of fire;

(2) coating with high efficiency, small loss of paint, paint utilization rate of up to90% ~ 95%;

(3) film thickness, strong adhesion, good coating quality, various parts such as inner layer, depression, workpiece welding joint can obtain uniform, smoothfilm, solves the problem of complex shape workpiece coating other coating method;

(4) the construction of high production efficiency, can realize the automation ofcontinuous production, improve labour efficiency;

(5) complex equipment, high investment cost, large power consumption, hightemperature drying and curing requirements, coating, coating managementcomplex, construction condition strictly, and the need for wastewater treatment;

(6) only use water soluble paint, does not change color in the coating process,coating is not easy to control long storage stability.

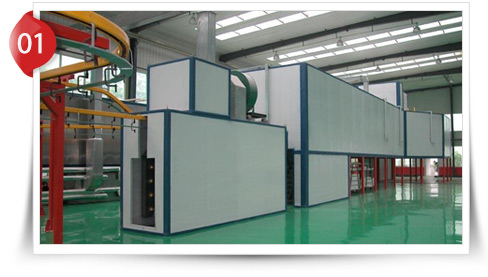

Electrophoresis painting equipment:

Electrophoretic coating equipment is composed of electrophoresis tank, a stirring device, a filtering device, coating, coating temperature adjusting devicemanagement device, DC power supply device, electrophoresis coating after washing device, ultrafiltration equipment, baking device, a spare tank etc..

The size and shape of the electrophoresis tank should be determinedaccording to the workpiece size, shape and construction technology. In a certain distance between the poles of the guarantee conditions, should as far as possible to design smaller. Slot is provided with a filtering device and a temperature adjusting device, so as to ensure the temperature of liquid paintcertain and remove impurities and air bubbles in the liquid circulating paint.The stirring device can make the liquid paint work kept uniform, multi usecirculating pump, liquid paint cycle per hour on average 4 to 6 times, when the circulation pump is started, the liquid paint liquid tank should be uniformturning. Coating management device is added to adjust the coatingcomposition, control of bath pH, removal of neutralizing agent and using ultrafiltration device eliminate low molecular weight with ingredients such asmembrane electrode. Electrophoresis power choice, usually adopts DC power supply. Rectifier equipment can use silicon or silicon controlled rectifier. The current size and coating properties, temperature, work area, electricity is related to the mode, generally 30 ~ 50A/m2. Washing device used for washingthe workpiece electrophoretic coating before and after, generally with thedeionized water, but need to pressure equipment, commonly used is a washingnozzle with a spiral body. Baking device used to facilitate drying film-formingelectrophoretic coating, using resistance furnace, induction heating furnaceand the infrared curing equipment. Drying room designed to heat three section of preheating, heating and, should be based on the formulation of coatingsand the workpiece situation.

专注电泳设备研发10年。全国十佳优秀电泳涂装设备企业之一,国际质量体系IOS9001认证。 已为富士康/比亚迪/吉利汽车/中国一汽等众多企业提供电泳设备产品和服务;在电动三轮车,汽配,轮毂、锯片、灯饰、五金等行业有着丰富的经验。

我司拥有电泳涂装线专业技术人员达70多人,产品远销韩、印尼、中东、越南、缅甸、俄罗斯等十多个国家和地区。且所有产品均自主生产,电泳涂装线配件都采用进口品牌或国产优质品牌以保障品质。

您只需要说明工件的材质,尺寸、产量、和所电泳的颜色,我司即可免费制作出一套量身定制的电泳生产线方案,让您一目了然。 同时可以短期内免费为您培训一批电泳现场操作人员以保证电泳生产车间的正常生产运行,并根据您的需要推荐经验丰富的电泳老师供您聘用。

我们不仅提供上门指导,上门安装电泳设备以及员工操作培训; 同时提供12个月的质量保证.为提高服务效率我司开通24小时直线售后服务,且在广东、浙江、江苏、河南、河北、陕西、北京、南京、辽宁等均设有经销商和办事处为您提供快捷的售后服务。

Projects Video

2023-02-10

2022-11-30

2022-11-30

2022-11-16

2022-10-25

2022-10-06

2022-09-29

2022-09-13

2022-09-06

2022-04-18

2022-03-22

2022-03-22

2022-03-10

2021-12-30

2021-12-29

2021-11-18